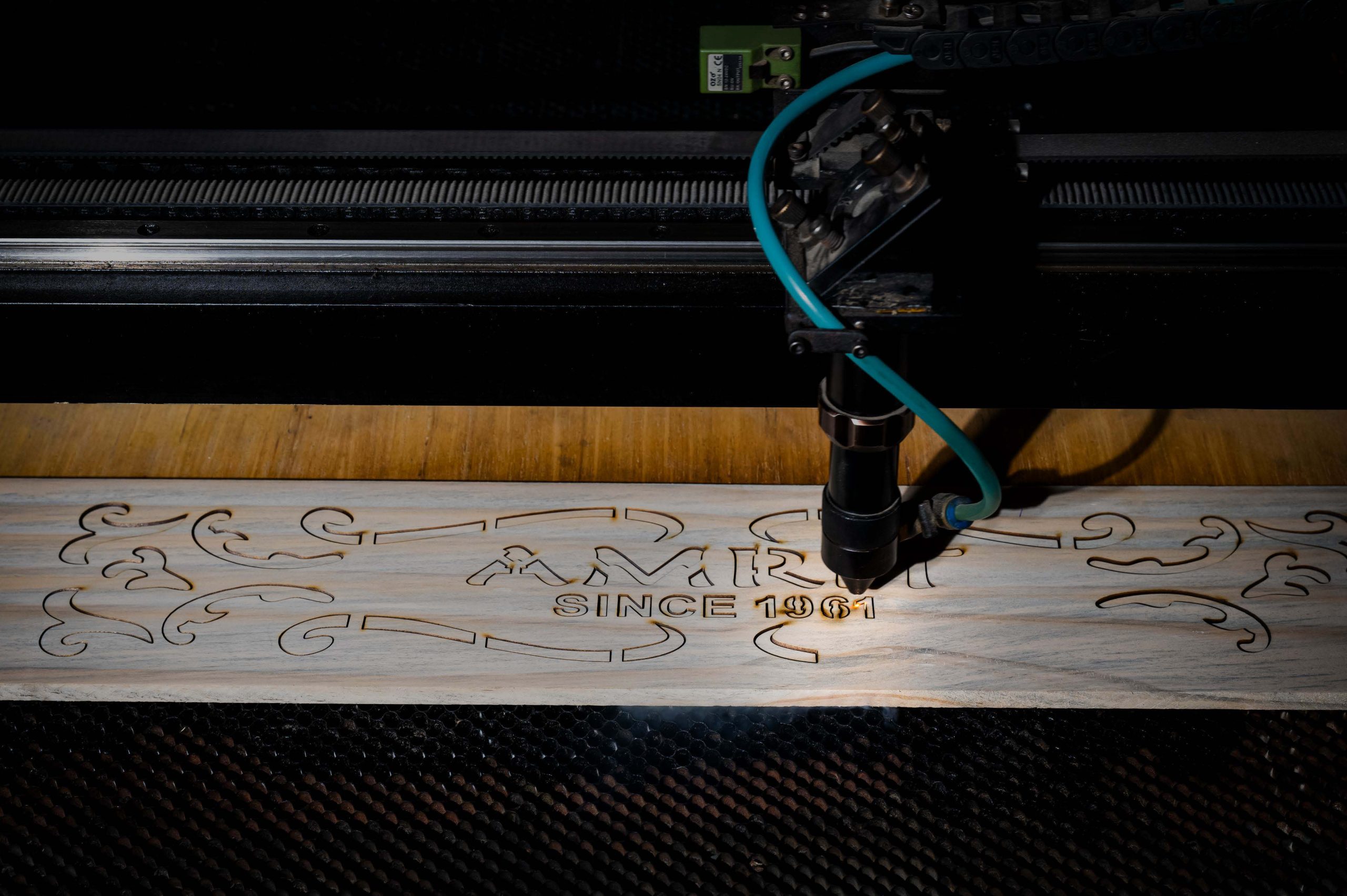

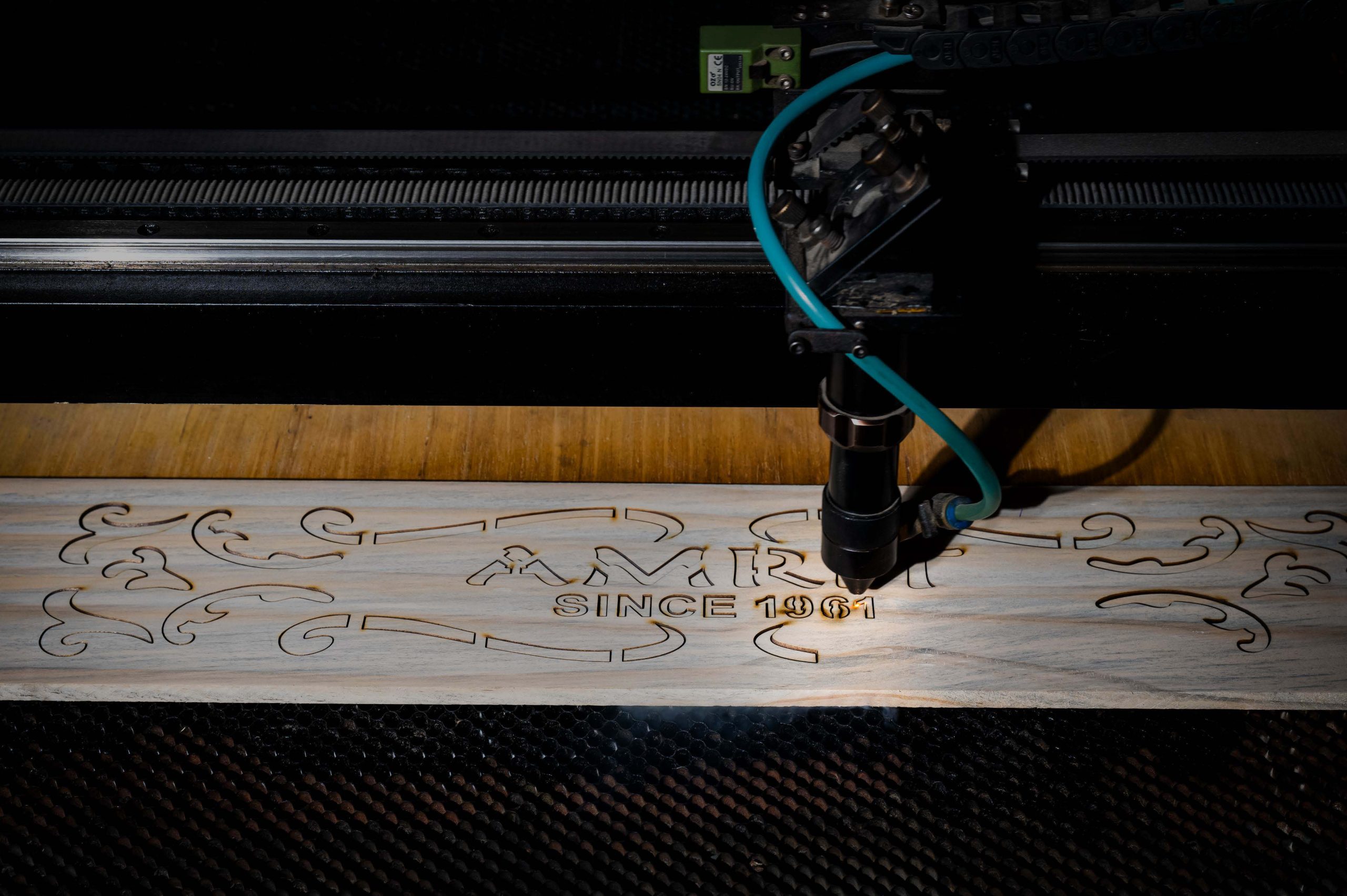

A seasoning kiln is a specialized chamber designed for the controlled drying of timber, and it is equipped wit h advanced systems to regulate both temperature and humidity levels to achieve optimal drying conditions. Within the kiln, arrangements are made for the precise heating and dehumidification of the air, ensuring that the drying environment can be tailored to the specific requirements of the wood species being processed. This conditioned air is then circulated evenly throughout the chamber to maintain uniform drying across all timber surfaces. The timber is stacked systematically inside the kiln to facilitate effective air flow and maximize exposure to the drying conditions. To enhance the efficiency of the process and accelerate the removal of moisture from the wood, powerful fans are installed to circulate the air rapidly and uniformly over and around the timber stacks. This controlled drying process helps reduce the risks of defects such as warping, splitting, or fungal growth, thereby improving the quality and durability of the seasoned timber for various end uses in construction, furniture-making, and other woodworking industries.

The harmonium produces sound using small, finely tuned metal strips known as reeds, which vibrate freely when air flows across t hem. This met hod of sound generation is the same as in instruments like the accordion, which also rely on free-reed mechanisms. Each note on the harmonium has at least one corresponding reed, carefully designed to produce a specific pitch.

Above every reed is a small air hole covered by a leat her valve that stays closed until a key is pressed.

When a key on the harmonium’s keyboard is pressed, it opens the valve above the corresponding reed. This allows air, which is stored under pressure inside the harmonium’s bellows, to flow through the open valve and pass over t he reed. The moving air causes the reed to vibrate rapidly, producing a musical tone that matches the pressed key. The volume and sustain of the note can be controlled by how steadily the air is pumped.

Once the key is released, a spring mechanism pushes it back to its original position. This causes the valve to close, cutting off the air flow to the reed. As the air stops, the reed ceases to vibrate, and the sound fades out. This process, involving air flow, mechanical action, and vibration, enables t he harmonium to create its rich and expressive tones, making it a popular instrument in classical, devotional, and folk music traditions.

In addition to wood, several other materials are integral to the construction and functionality of a harmonium. Leather is commonly used for valve seals due to its flexibility, airtightness, and durability, ensuring precise airflow control and efficient valve operation. Metal is employed for key components such as screws, key and bellows springs, and, most importantly, the reeds. These metal parts are selected for their strength, resilience, and stability, with the reeds crafted from tempered alloys to produce clear, accurate tones.

The key surfaces are typically coated with synthetic plastic layers to provide a smooth playing feel and protect against wear and moisture. This coating also gives the keys a refined appearance, often resembling traditional materials like ivory or ebony. Visible wooden parts of the harmonium are treated for both protection and aesthetics. They are usually finished with varnish, sometimes pigmented to enhance the natural grain or color of the wood. Depending on the desired look, the finish may be polished to a high-gloss, left semi-matte, or waxed to create a more natural and traditional appearance. These finishing touches not only enhance the instrument’s beauty but also help protect it from environmental damage and aging.

The seasoning Kiln is a chamber equipped with arrangements for heating and dehumidifying the drying air to desired conditions of temperature and relative humidity and its circulation over the surfaces of timber stacked inside. Fans are used for faster circulation of air.

The sounds of the harmonium are generated by freely vibrating metal platelets – the so-called reeds – the same mechanism of sound generation as in the accordion. There is at least one reed for each note. Small air holes are positioned above all reeds, which are closed on top by leather seals like valves. By pressing down a key on the keyboard, the valve above the respective reed opens; the air accumulated inside escapes, blows at the reed and creates a sound. By releasing the key, it will be pressed back into its original position by means of a spring, the valve closes, the air stream stops, and the sound ceases.

The air for blowing the reeds is created by bellows, which in most harmonium models are fitted into the bottom of the instrument, invisible from outside. Visible are however the outer bellows at the back of the harmonium, blowing up the inner bellows using pumping movements and thus building up the required air pressure. Even if there is only little air inside the inner bellows, inbuilt springs see to it that the air escapes with a reasonably even pressure for playing.

Most harmoniums have two or three separate reed sets placed inside in air chambers sealed off from one another. In most cases, the corresponding notes of the reed sets lie in octave’s range to each other. A distinction is made between three pitches: the deep bass octave, the middle male octave and the high female octave. An adjustment of the register at the front of the harmonium allows the selection of a respective air chamber from which the air of the inner bellows should escape. In this way, one or a free combination of the existing reed sets can be used for playing.

The outer frame, inner air chambers and key mechanisms are made from wood. The quality of the wood as well as the precision of manufacturing plays a major role. Bad wood quality or sloppy processing may result in parts jamming, ripping or distorting. Thus unplayable or permanently resonating notes or air loss creates malfunctions.

Leather is also used for the valve seals. Metal is used for screws, key springs, bellows springs, and reeds. The key surfaces are layered with plastic coatings. Visible wooden surfaces are polished with varnish, partly with added pigments, and either polished to high-gloss or semi mat or they are waxed.

© Copyright 2025, All Rights Reserved by AMRIT HARMONIUM | Design & Developed by WebHopers